Kentucky Hemp Harvest Postcard

This postcard from 1910 shows the importance of hemp as a crop in Kentucky, US. It eventually stopped being profitable after slavery was abolished.

Industrial hemp is one of the oldest agricultural crops on Earth and it has been used to make thousands of different products. Varieties cultivated for industrial use contain barely any intoxicating substances.

Late 19th century postcard depicting a girl from Brittany (France) making hemp threads.

Industrial hemp is one of the oldest cultivated crops on Earth. Varieties cultivated for industrial use contain barely any intoxicating substances, although they are of the same family as medicinal marijuana and the cannabis sold in Amsterdam’s coffee shops today. The bast fibres surrounding the woody stem of the cannabis plant are the strongest natural plant fibre in existence, and they are one of the many advantages of industrial hemp.

The collection of hemp artefacts on display in our museums includes unique prints and book illustrations from the 19th and 20th centuries, rare photos of hemp cultivation in Italy and Eastern Europe, and antique tools that were used in the process of cultivating hemp, all of which stand witness to the long history of this plant. Even though these images often paint a romantic picture of rural life, this was not the reality of the situation. Hemp processing was hard labour and it would take whole families’ every effort just to earn a living at it.

Check out these collection items

This postcard from 1910 shows the importance of hemp as a crop in Kentucky, US. It eventually stopped being profitable after slavery was abolished.

This postcard is an engaging testimony to the long history of hemp in France.

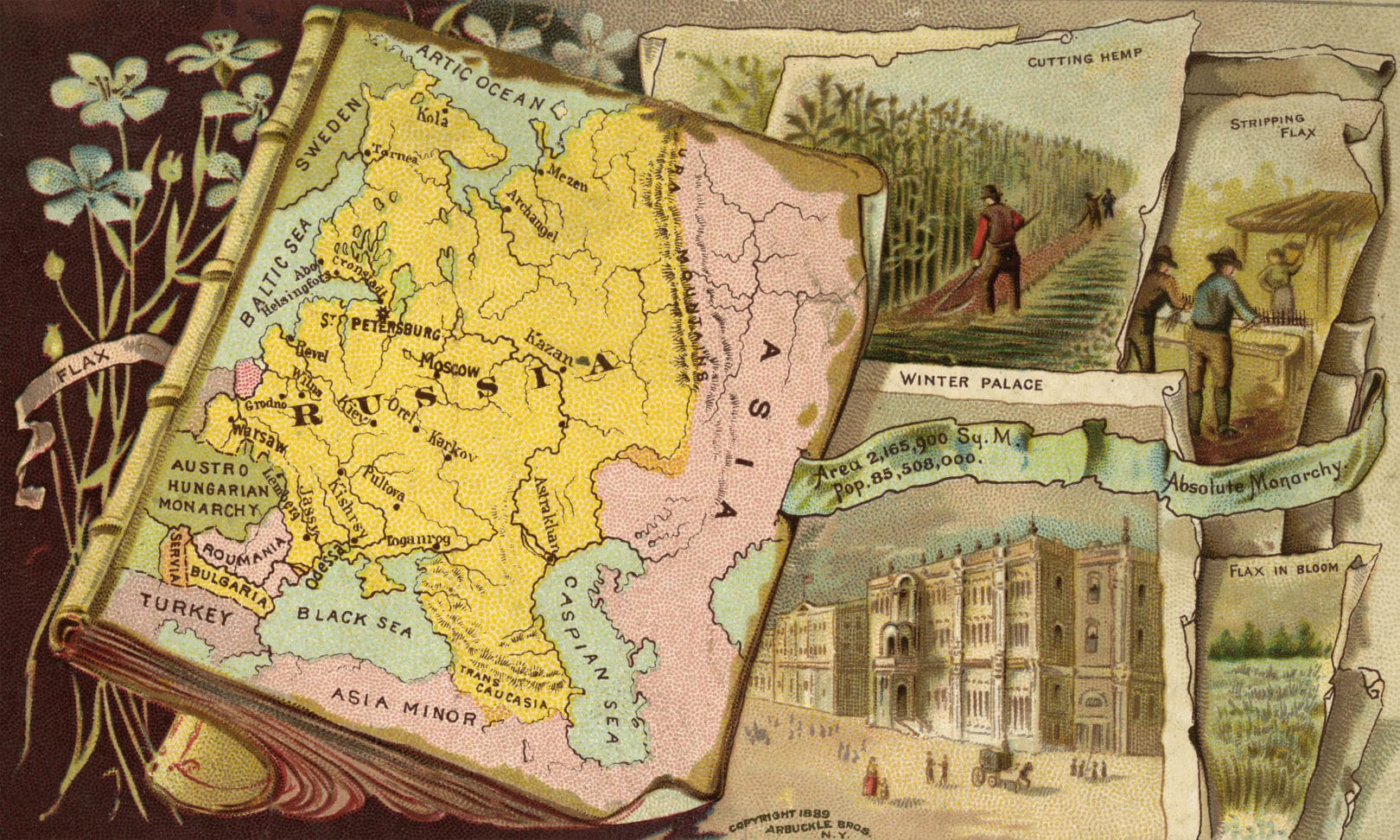

Since the eighteenth century, Russia was the largest hemp producer in the world.

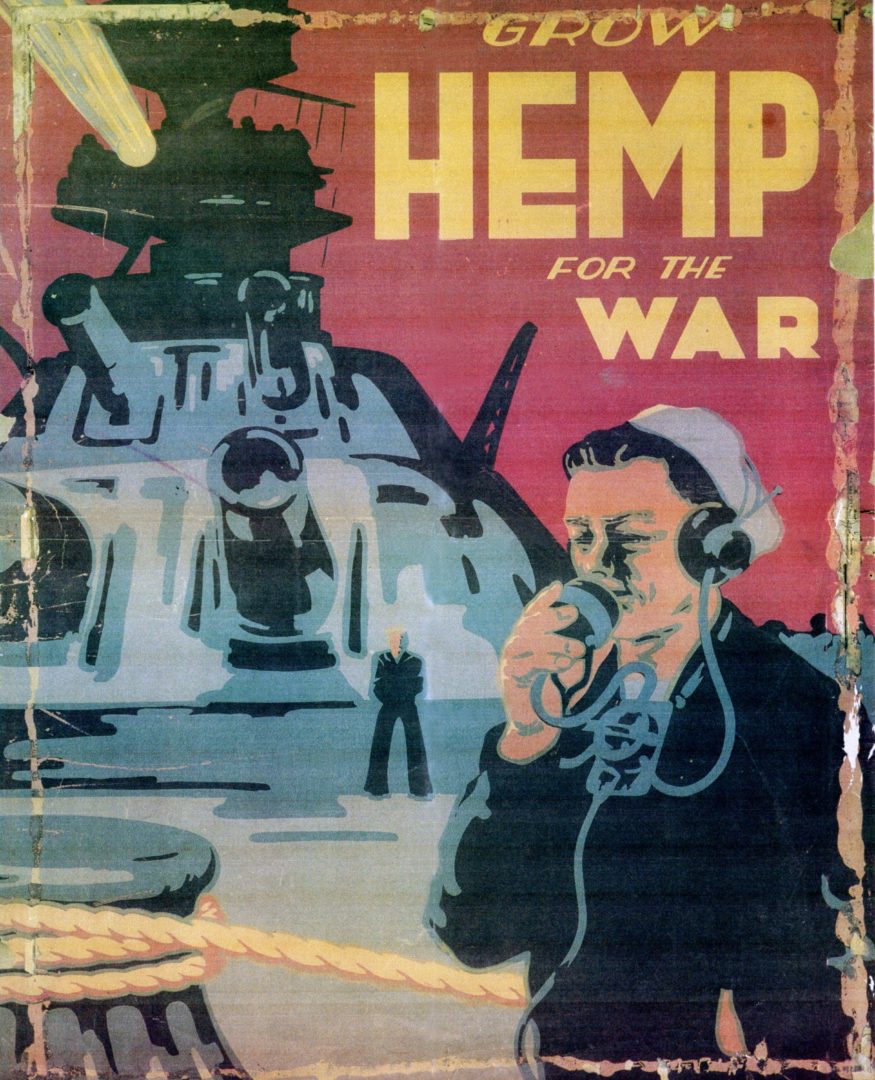

Hemp for Victory is a short propaganda film by the United States Department of Agriculture from 1942.

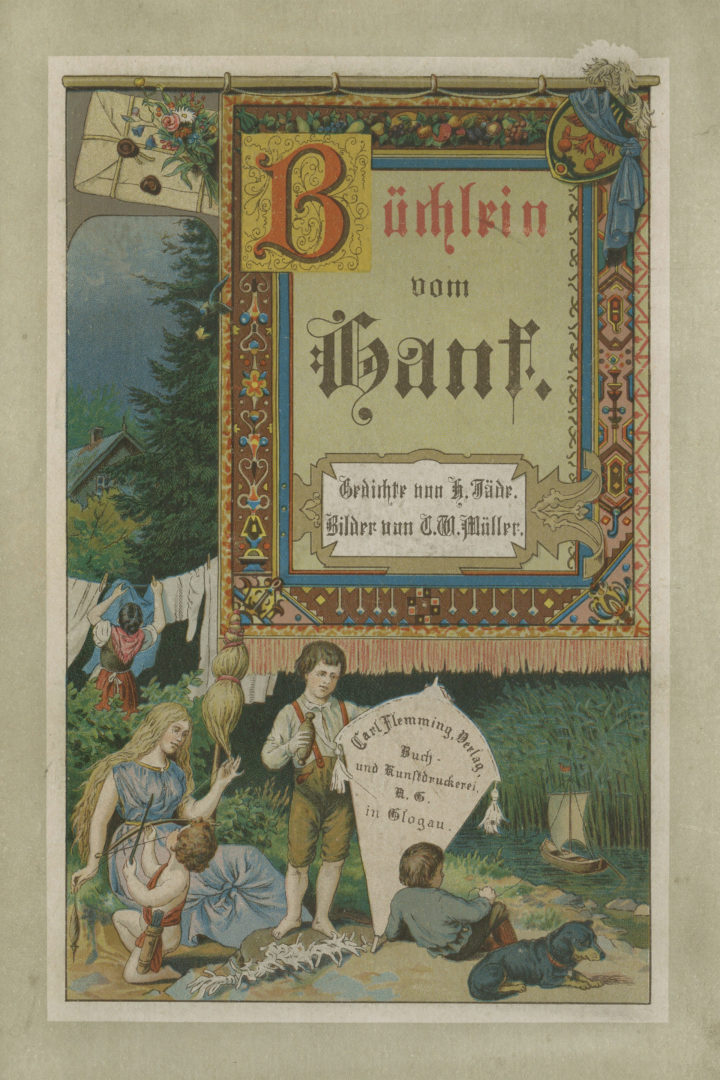

Before the First World War, German farmers were encouraged to grow hemp to aid in the return of a self-sufficient German economy.

Sign up to get the latest news about the museum, upcoming exhibitions and events.

Oudezijds Achterburgwal 148

+31 (0)20-6248926

amsterdam@hashmuseum.com

Monday to Thursday: 12:00 – 20:00

Friday to Sunday: 10:00 – 22:00

More information

Carrer Ample 35

+34 93 319 75 39

barcelona@hashmuseum.com

Every day: 11:00 – 20:00

More information

© 1987 - 2024 Hash Marihuana & Hemp Museum. All Rights Reserved. CSS Status 404